Use Wireless Energy Harvesting Sensors to Simplify HVAC Installations and Retrofits

There was a time I used to visit some customers located in fun buildings like renovated barns and former warehouses that had been transformed into office spaces. That’s ok, for a few people, but once you start putting hundreds of people in a facility built before modern heating, ventilation, and air conditioning (HVAC) systems, air circulation becomes a challenge. And it’s not just about comfort, as healthy ventilation is important for everyone; old buildings are quaint but surprisingly difficult to retrofit for HVAC.

One customer, for example, was located in an old, very large office building. The company had tried to modernize the ancient building with various degrees of success. One of the biggest problems was ventilation, so the company installed ducts and vents with a modern HVAC controller.

However, an open window in the summer or winter in that building was a very big deal, resulting in an enormous amount of wasted energy as the HVAC system worked to meet the thermostat’s setting. I would have placed reed sensors on the windows to detect if a window was open so the HVAC system could respond intelligently. However, window sensors at that time required running wires between the sensor and the HVAC controller for both signal and power, leaving unsightly wires and a less-than-professional appearance.

Window reed sensors later evolved so they were battery-powered and sent a wireless signal to an HVAC controller with a suitable receiver. I’ve installed wireless reed sensors as part of a friend’s burglar alarm system. Battery-powered wireless sensors have the advantage of eliminating the extra wiring, but with two-year battery life, they require maintenance for battery replacement.

These are, of course, small batteries that come with their own problems, as they are often misplaced or missing in the maintenance cabinet. The batteries also degrade in storage over time, as I learned when I discovered one of the reed switches I installed had a dead battery. To make things worse, it was an odd-sized battery that required a short trip to the store to buy a replacement. This begged the question: Do I buy spare batteries that may sit on a shelf for two years before being needed?

Energy harvesting solves installation and maintenance dilemma

Figure 1: The Illumra E9T-MDCCP wireless magnetic reed switch is suitable for detecting a door or window opening. It requires no batteries and is kept charged by the rectangular solar cell visible on the switch above. (Image source: Illumra)

Figure 1: The Illumra E9T-MDCCP wireless magnetic reed switch is suitable for detecting a door or window opening. It requires no batteries and is kept charged by the rectangular solar cell visible on the switch above. (Image source: Illumra)

A modern engineering solution would be to install wireless window sensors with energy harvesting capability that completely circumvent the need for battery replacement. A good example is the E9T-MDCCP from Illumra (Figure 1). A manufacturer of self-powered wireless controls, Illumra has a whole family (E9T-MDCCP/E9T-MCS) of 902 megahertz (MHz) wireless window and door sensors. These can transmit to a compatible receiver at a distance of up to 60 feet (ft.), depending on the environment, using the EnOcean protocol.

The E9T-MDCCP charges a small rechargeable battery using a rectangular solar cell on the body of the switch. The sensor has a magnetic reed switch that is activated when it is next to the supplied magnet, both of which are attached by either adhesive or tamper-resistant security screws.

In operation, the reed switch’s magnet needs to be within 4.5 millimeters (mm) of the sensor to generate a closed condition. Upon closing, the reed sensor will make a faint clicking sound. When transitioning between an open and closed position, an LED on the sensor will blink. This helps installers properly align the sensor and also helps with any diagnostics of the system.

When fully charged, the E9T-MDCCP can continue to operate in darkness for up to five days. If the rechargeable battery is fully depleted, it requires less than 2.5 minutes at 25°C ambient of 400 lux natural or artificial illumination to charge until the switch becomes operational again. The solar cell needs only about 2 hours per day of 200 lux illumination to maintain consistent and reliable switch operation. With no batteries needing regular replacement, the only maintenance required is to make sure the switch and magnet are still attached to the wall and that nobody has messed with the security screws.

The E9T-MDCCP can operate from -20°C to +60°C, appropriate for most buildings and enterprise applications, while also ensuring the switches are not damaged if left in non-temperature-controlled environments, such as parts storage closets.

While the sensors can be used for windows or doors and are appropriate for HVAC, there are many more applications, including automatic door sensing, refrigerator and security doors, supermarket coolers, and alarm systems.

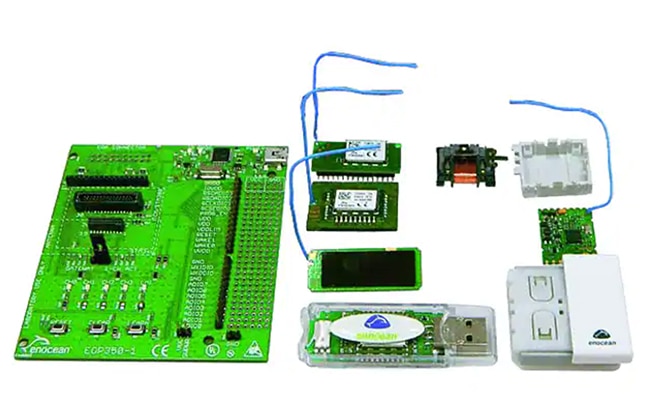

If you’re interested in energy harvesting in general, take a look at EnOcean’s array of wireless modules and development kits. There’s lots to play with here, including the EDK350U Dolphin series energy harvesting transceiver evaluation kit (Figure 2).

Figure 2: The EDK350U energy harvesting kit includes everything you need to start exploring wireless energy harvesting design ideas, including a solar sensor, mechanical energy generator, and a sensor adapter. (Image source: EnOcean)

Figure 2: The EDK350U energy harvesting kit includes everything you need to start exploring wireless energy harvesting design ideas, including a solar sensor, mechanical energy generator, and a sensor adapter. (Image source: EnOcean)

The EDK350U Dolphin kit includes a demo board, USB gateway, RF transceiver module, a sensor module adapter, a solar-powered temperature sensor, a mechanical energy generator, a transmitter module, and all necessary cabling and software development interfaces.

Conclusion

Sometimes legacy building systems can appear to resist modernization unless you want to sacrifice look, style, and employee comfort. First, there were wireless sensors, and now there are wireless and “batteryless” sensors. Done right, your current modernization project and future designs can be improved to provide efficient and reliable performance with a professional look and minimal maintenance.

I know for sure the Illumra wireless energy harvesting window and door sensor would have saved the day at my legacy building, keeping everyone comfortable.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum