Aan de slag met sensorloze veldgeoriënteerde regeling van BLDC-motoren en Infineon

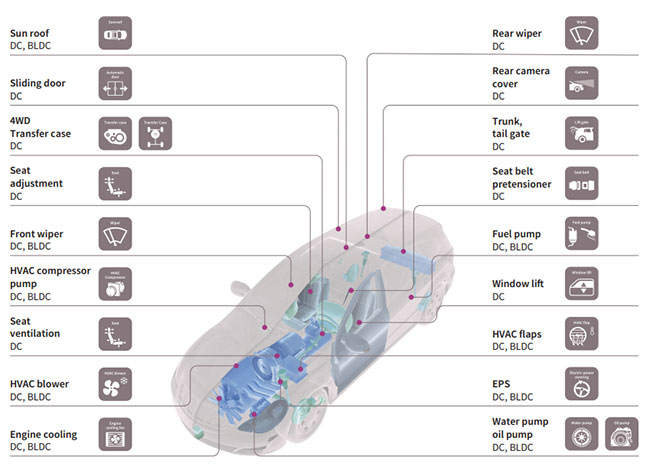

Elektromotoren zijn overal, in onze huizen, op onze werkplekken en in onze voertuigen. Neem bijvoorbeeld een typische moderne auto: die heeft gemiddeld zo'n 35 motoren verdeeld over het hele voertuig. Zowel standaard als borstelloze (BLDC) gelijkstroommotoren worden gebruikt in toepassingen van brandstofpompen tot raambediening (Afbeelding 1).

Afbeelding 1. Veel voorkomende toepassingen van standaard en borstelloze (BLDC) gelijkstroommotoren. (Bron afbeelding: Infineon)

Afbeelding 1. Veel voorkomende toepassingen van standaard en borstelloze (BLDC) gelijkstroommotoren. (Bron afbeelding: Infineon)

Met de toename van elektrische en hybride voertuigen is de trend naar een nog groter aantal motoren per voertuig. Naast de automobielindustrie worden gelijkstroom- en BLDC-motoren in veel toepassingen in de industriële automatisering, besturing en robotica toegepast.

BLDC-motoren worden algemeen in veeleisende toepassingen gebruikt vanwege hun betere prestaties ten opzichte van gelijkstroommotoren met borstels. BLDC-motoren zijn efficiënter, hebben een langere levensduur en bieden een hoger koppel per gewichtseenheid dan standaard gelijkstroommotoren. De nadelen van BLDC-motoren zijn een hogere prijs en de noodzaak van een extra regelschakeling.

Ikzelf heb onlangs mijn slagboormachine met accuvoeding van een standaard naar een borstelloze gelijkstroommotor geüpgraded. De verbetering in koppel en accuduur was geweldig en maakte de extra kosten de moeite waard.

BLDC-motoren

BLDC-motoren zijn een variatie van traditionele standaard gelijkstroommotoren. Het elementaire verschil is dat voor een BLDC-motor de stroomomkering elektronisch moet worden verzorgd in plaats van mechanisch met borstels. De rotor van een BLDC-motor bestaat uit permanente magneten, de stator is met een overeenkomstige set polen gewonden. Een regelschakeling wordt gebruikt om de windingen aan te sturen en een draaiveld te genereren. Doordat de rotor draait om zich met het roterende statorveld uit te lijnen worden beweging en koppel gegenereerd.

Sensorloze veldgeoriënteerde regeling (FOC)

Sensorloze veldgeoriënteerde regeling (FOC) is een van de methodes die gebruikt worden om de snelheid en het koppel van een BLDC-motor te regelen. Veldgeoriënteerde regeling (ook vectorregeling genoemd) is een techniek waarbij een 3-fasen sinusvormige modulatie wordt gegenereerd die in frequentie en amplitude kan worden gemoduleerd. Er worden berekeningen gebruikt om de driefasen signalen in twee fasen om te zetten die eenvoudiger te regelen en te implementeren zijn in de regelschakeling van de motor. Met sensorloze regeling zijn geen positiesensoren nodig, maar wordt de elektromotorische tegenkracht (EMF) gebruikt om de positie van de rotor te bepalen.

Sensorloze FOC in een microcontroller implementeren

De signalen moeten worden gemeten en er moeten berekeningen worden uitgevoerd om een sensorloze FOC te implementeren. Een microcontroller met de noodzakelijke prestaties en set randapparaten is prima bruikbaar om deze functionaliteit te implementeren. De Infineon TLE9879QXA40 is een SoC met driefasen motorregeling op één enkele chip waarin een Arm® Cortex®-M3 core geïntegreerd is (Afbeelding 2).

Afbeelding 2. Blokdiagram van de TLE9879x. (Bron afbeelding: Infineon)

Afbeelding 2. Blokdiagram van de TLE9879x. (Bron afbeelding: Infineon)

Hij bevat zes volledig geïntegreerde NFET-drivers om een driefasenmotor via zes externe vermogens-NFET's aan te drijven, een ladingspomp voor laagspanningswerking en een programmeerbare stroom met hellingsregeling voor geoptimaliseerd gedrag van de EMC. De randapparatuur bestaat uit een stroomsensor, een successive approximation ADC gesynchroniseerd met de uitlees- en vergelijkingseenheid voor de PWM-regeling en 16-bit timers. Bovendien beschikt hij over een geïntegreerde LIN-zendontvanger om communicatie met het apparaat mogelijk te maken plus een aantal universele I/O's. Verder zit er een lineaire spanningsregelaar op de chip om externe belastingen te voeden.

De TLE9879QXA40 van Infineon is een goede oplossing om veldgeoriënteerde regeling voor BLDC-motoren te implementeren. Hij heeft de prestaties en features om een krachtige, voordelige driver voor BLDC-motoren te implementeren die een minimale ruimte op de printplaat inneemt. In de diepgaande toepassingstip 'Sensorless Field Oriented Control with Embedded Power SoC' wordt de FOC-theorie en de mogelijke implementatie van het algoritme in detail beschreven.

Aan de slag

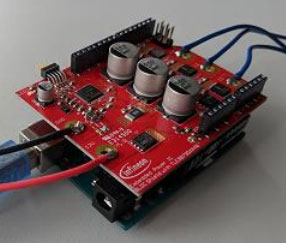

Het BLDC_SHIELD_TLE9879 goedkope evaluatieboard van Infineon is een eenvoudige manier om met een sensorloze FOC aan de slag te gaan. Hij is op de TLE9879QXA40 gebaseerd en bedoeld om in combinatie met een Arduino-compatibele basiskaart BLDC-motoren aan te sturen. In combinatie met een Arduino Uno kunt u een compatibele BLDC-motor in minder dan een uur laten draaien (Afbeelding 3).

Afbeelding 3. BLDC_SHIELD_TLE9879 op een Arduino Uno basiskaart geïnstalleerd. (Bron afbeelding: Infineon)

Afbeelding 3. BLDC_SHIELD_TLE9879 op een Arduino Uno basiskaart geïnstalleerd. (Bron afbeelding: Infineon)

Schema's, een Arduino bibliotheek en volledige documentatie voor de BLDC_SHIELD_TLE9879 zijn te vinden op https://github.com/Infineon/TLE9879-BLDC-Shield. Bij mijn onderzoek voor deze blog heb ik enige tijd met de Uno en shield gewerkt om bekend te raken met het aansturen van een BLDC-motor. Configuratiestappen, testcode en gedocumenteerde referenties staan in mijn project Driving a BLDC Motor with Infineon’s TLE9879Qx 3-Phase Motor Driver Shield op het DigiKey TechForum.

Toepassing ontwikkelen

Voor wie geïnteresseerd is om dieper in ontwerp en ontwikkeling op basis van de TLE9879Qx te duiken, biedt Infineon extra bronnen. Om te beginnen is broncode voor de firmware op de BLDC shield beschikbaar als Keil uVision projectbestanden. De projectbestanden zijn onderdeel van de softwaredownload 'BLDC Shield for Arduino with TLE9879QXA40' van Infineon via de link BLDC_SHIELD_TLE9879 op de shield projectpagina. Naast de BLDC shield zijn bovendien het referentieontwerp voor de REF_WATERPUMP100W pomp en het referentieontwerp voor de REF_ENGCOOLFAN1KW ventilator bij DigiKey beschikbaar.

Conclusie

Het evaluatiebord BLDC_SHIELD_TLE9879 van Infineon biedt een snelle, voordelige manier om aan de slag te gaan met sensorloze FOC om BLDC-motoren aan te sturen. Het bord is tevens een goed startpunt voor meer geavanceerde gebruikers die geïnteresseerd zijn om de TLE9879QXA40 te evalueren en met de meegeleverde broncode aan de slag te gaan.

Externe referenties

1 – Infineon. 'Motor Handbook'

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum