Flexible Connectors, Limitless Possibilities for Smaller Spaces

Microminiature and flex connectors were initially designed as a solution for ever-shrinking handheld mobile devices, but these solutions have given engineers across a variety of applications and markets almost limitless flexibility by removing two of the most fundamental design constraints: size and structure. As more companies focus on designing their products to have feature-rich options, sleeker profiles, and modern user interfaces, the need for increased flexible print assemblies and more modularity continues to grow.

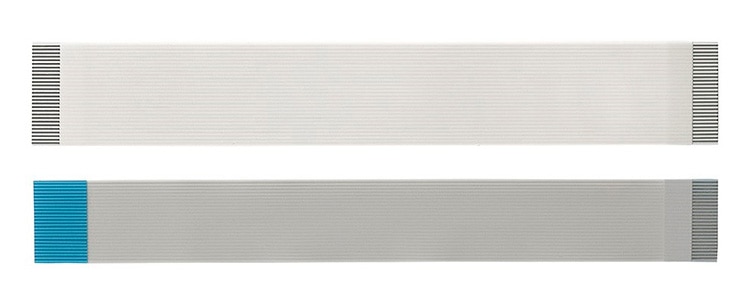

(Image source: Molex)

(Image source: Molex)

The increasingly common transition from push buttons and turn dials to touch screens on appliances result in the transmission of much more data in smaller spaces where soldered wires are no longer the best solution. Flexible flat cables (FFCs) and flexible printed circuits (FPCs) come in a wide range of circuit sizes and cable styles, providing a solution that can be bent, folded, and configured in just about any shape or thickness. Combined with the ability to withstand high temperatures and built-in contact reliability, these small, flexible connectors remove the most common limitations when it comes to designing an electronics package.

Small Parts, Big Roles

FFC and FPC connectors are used in a variety of ways, depending on the applications they are built into. But regardless of application, these solutions focus on connecting in smaller form factors, gaining more flex retention, having more tolerance to the environment, and performing better in higher data rates—all features that contradict each other in legacy connector solutions.

While micro and flex connectors open up a new world of possibilities when it comes to engineering and design, they come with their own unique set of challenges. New products that are fully embracing a more complex module design due to FPC/FFC solutions often require a specific number of signal circuits and PCB design. DigiKey works with suppliers such as Molex that carry a wide variety of connector combinations, providing design flexibility and the ability to choose solutions that are the perfect fit for any application.

These specialized connectors are often used in harsh environment applications, where contact reliability is crucial—and a challenge when the components are as small as a grain of rice. Using connectors with dual-contact terminals and latches can provide secure connectivity in these challenging environments. Additionally, the increase in product densities and performance often requires components to function in high-temperature applications. Ensuring that even the thinnest connectors can withstand extreme temperatures should give engineers the confidence to use them in high-performance products.

Streamlining the Supply Chain

The ability to work with a single supplier for all FFC and FPC interconnect requirements simplifies the supply chain—DigiKey works with Molex, which offers various FFC and FPC connector configurations, circuits, sizes, and specifications.

Incorporating small, flexible connectors into a product’s design also helps streamline the supply chain and reduces assembly and handling costs. For example, a smartphone camera is usually constructed by a camera module manufacturer that combines disparate components of the OEM’s choosing with an FPC cable extension. When the electronics manufacturer receives the camera module, they can simply plug the flex connector into the mainboard.

This solution creates additional value for equipment manufacturers during product testing. Because components and modules are growing more complicated, OEMs need the ability to connect a module to a testing apparatus to run tests, then disconnect it, and then connect it again for assembly. This sequence may occur multiple times if there is more than one test during the assembly process. These connectors make the process easier by establishing interconnects through a simple plugin operation.

The Molex Advantage

DigiKey offers Molex’s Easy-On product line, which contains about 70 series, ranging in size from that of a grain of rice to that of a pinky finger, and each series meets a different customer need. These broader series are often broken down into sub-series with different features, such as ranges of temperature tolerances.

Engineers at Molex’s Micro-Solutions Business Unit specialize in micro-miniature designs. The team’s extensive knowledge in the area of high-grade engineering plastics makes them a leader in molding tiny housings without deformation. Molex’s engineers also have extensive experience in designing and forming metal into tiny but complex terminals, allowing for both seamless connection and locking capabilities. DigiKey carries Molex’s Easy-On FFC/FPC connectors in a wide range of circuit sizes that operate in high temperatures and maintain secure contact reliability even in the harshest environments.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum